Vortex® is a sintered, porous metal that is heat treated to 43 HRc with porosity of 25% by volume. A system of interconnected pores with an average diameter of 7 (.0003″) microns is dispersed throughout the Vortex® material. Using Vortex® in appropriate areas, eliminates gas buildup, reduces injection pressure, lowers cycle times, gloss levels and substantially reduces scrap and reject rates.

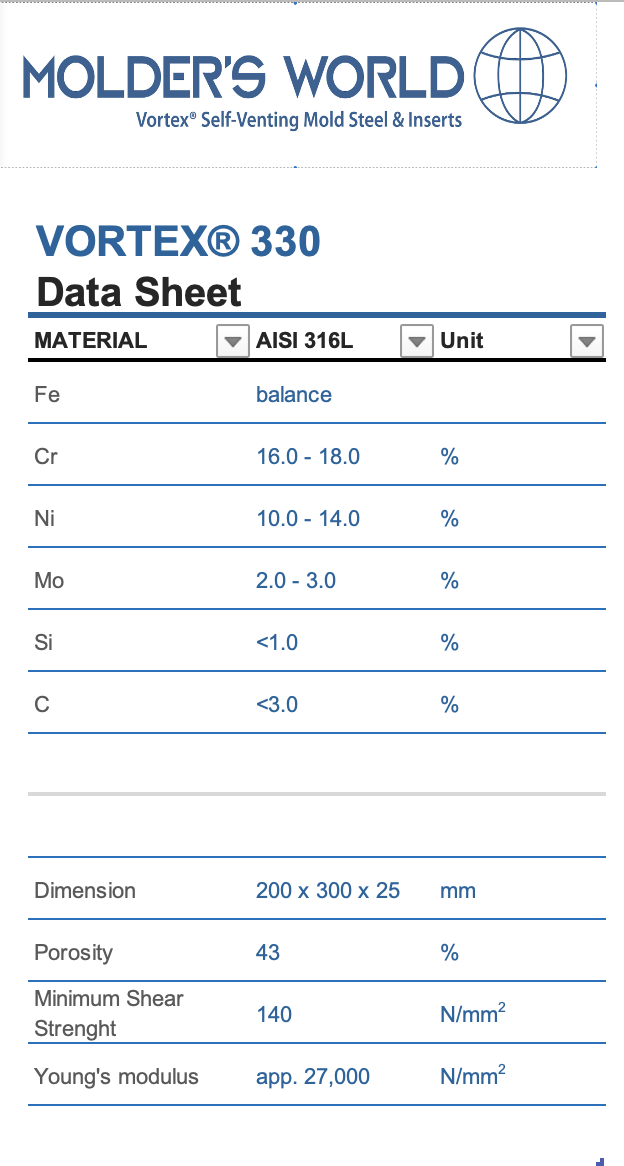

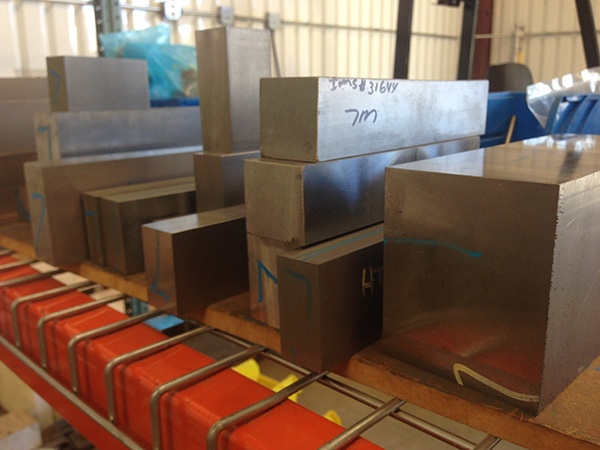

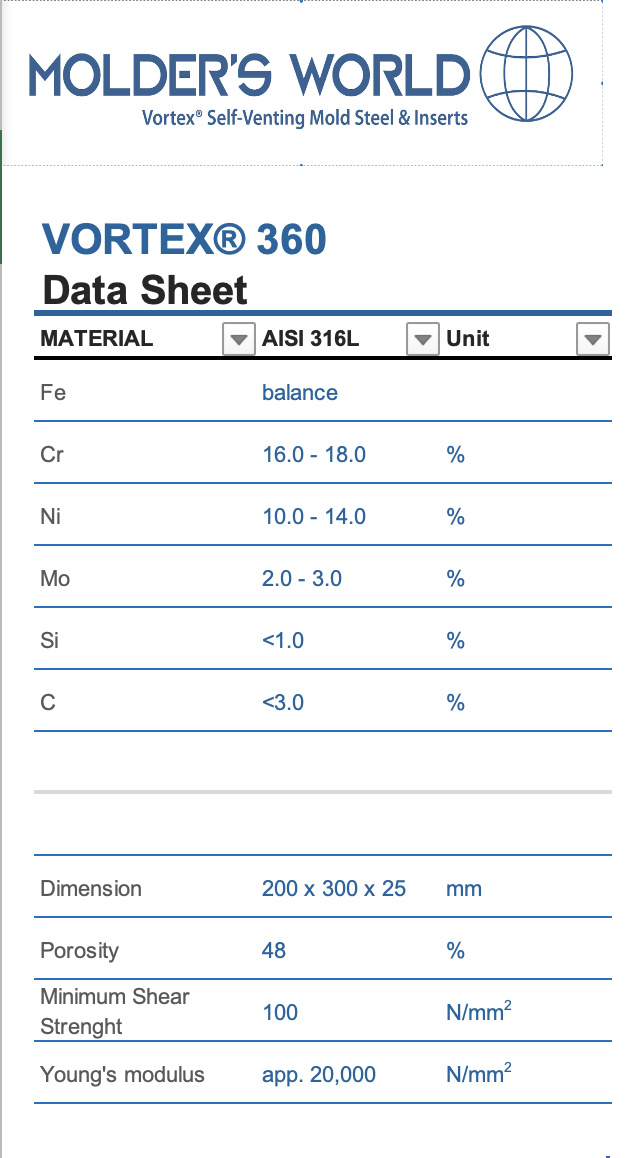

Vortex® 330 & Vortex® 360

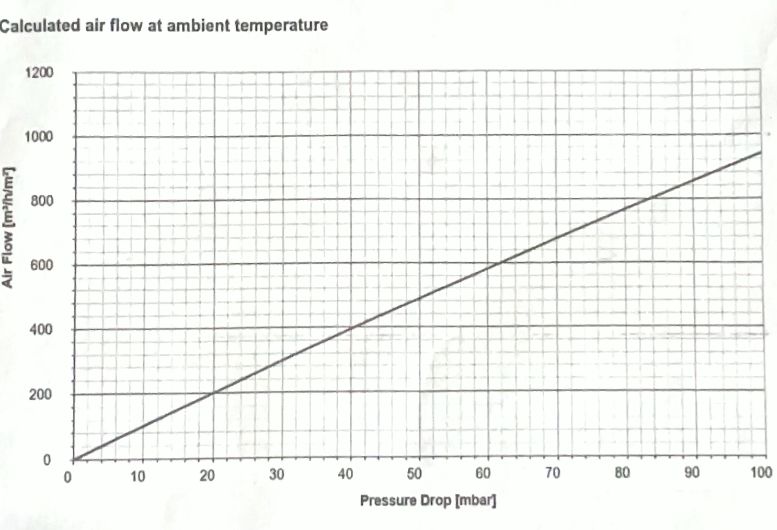

Vortex® 330 and Vortex® 360 are porous, self-venting mold steels produced with blow molding and vac-form molding in mind. The large pores (30 micron and 60 micron, respectively) allow for optimal gas venting in hard to fill molds while still allowing for structural integrity in the tool.

BioCorr® Rust Preventative

BioCorr® Rust preventative is a water-based, biobased, and biodegradable rust preventative that is intended for preservation of metals in storage and during transportation. BioCorr® Rust Preventative provides multi-metal protection and is an excellent enviornmentally sound alternative to petroleum derived products.

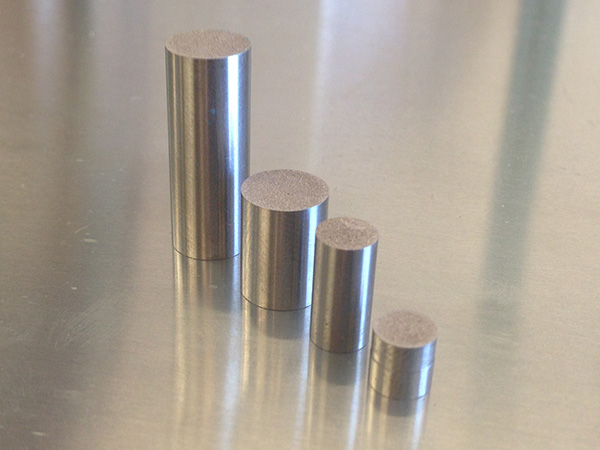

Custom made Porcerax II® inserts and Vortex® core and press in pins

Molder’s World Inc. is the industry leader in Porcerax II® inserts and Vortex® core and press in pins. We can machine Porcerax II® inserts and Vortex® core and press in pins to your exact specifications.

Custom made Vortex® ejector

Custom made Vortex® ejector pins can be a huge time saver. These pins can save you the time of taking apart the mold which adds up to a huge time saving. Molder’s World Inc. can custom make these to your specifications.

Venting Vortex® Pins and Core Pins

Vortex® venting core pins and press in pins are made to industry standard tolerances. These pins allow the molder to use a core pin that has a venting surface that is 25% micro-porous for maximum venting where you need it. These are made with Porcerax II®, in both 7 and 20 micron pores.